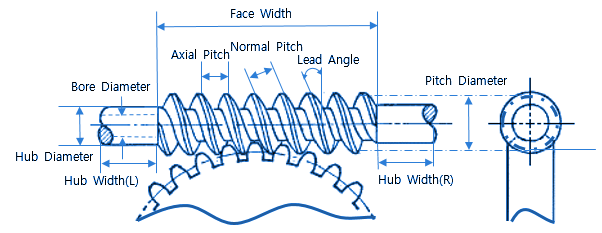

If the AC induction motor is 4 Pole AC asynchronous motor: 1380 rev/min. Gear speed reducer with 0.75Kw input power, transmission ratio 1:30, default service factor(f.s.) is 1.0, and gearbox transmission efficiency(η) :100%, 4 pole AC induction motor with 1440 rpm, How to calculate the gearbox output torque(T2) ? What are the units of output torque? How heavy goods can be lifted by this industrial Gearmotor?Ġ.75Kw( geared motor power) x9550x gearbox transmission efficiency x30 / input speed x service factor = gearbox output torque. The gear reducer output shaft is one position of output torque performance on the Gearmotor. The following situation is an example of the gearbox torque calculation, Customer can refer to the below information: The industrial gearbox is a relatively precise machine, its purpose is to decrease motor speed, increase output torque. Motor Power(HP or Kw)=Torque (N.m) /9550×Input Speed of motor Power(Kw) / Ratio / Service factor

Gearbox Output Torque Calculation Formula Ratio = number of revolutions of the motor output speed/gearbox output revolutions (“Ratio” also known as ” transmission ration”)

How to calculate gearbox output torque? ( gearbox output torque calculation formula)

0 kommentar(er)

0 kommentar(er)